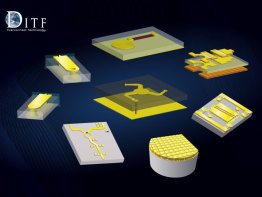

PCB Manufacture and Build-to-Print

● Thin Film Circuits

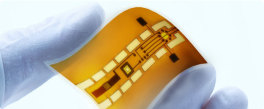

● Flexible Circuits

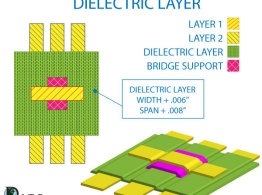

● Single and multi-layer

Processes:

CO2 laser drilling

Sputtering

Photolithography

(feature size to 0.00027" (6.86 um), tolerances to ±0.00005")

Electroplating

Electroforming

Electroless Ni/Immersion Au (ENIG),

Pre-deposited & patterned AuSn solder.

Laser trim

(Resistors, attenuators, complex circuits etc)

Diamond saw dicing

(parts sizes as small as 0201 devices)

Packaging

(bulk, waffle pack, Tape & Reel)

Services:

100% visual inspection

(MIL-STD-883)

DC & Electrical testing

S-Parameter

First Article Inspection (FAI)

Element Eval to MIL-PRF-38534 Class K

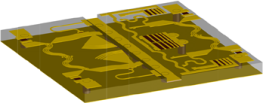

Microwave packaging and low level assembly

Substrates (include):

Quartz/fused silica,

Aluminum nitride,

Alumina,

Ferrite/garnet,

Titanates,

Glass,

Sapphire,

Silico,

Polyimide,

Resistor films

(TaN, NiCr)

● As-fired, lapped, polished

Conductive materials (include):

Nickel cobalt,

Nickel,

Copper,

Pure gold,

Hard gold,

Palladium,

Platinum,

Rhodium,

Features:

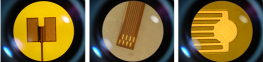

Conductors

(incl high power handling, High-Q, High Conductivity)

Resistor

Adhesion

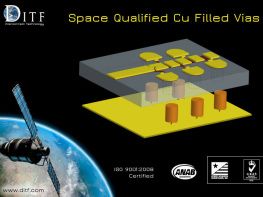

Plated Thru Holes & Filled Vias

(Copper, Gold; Space qualified Cu Filled Vias)

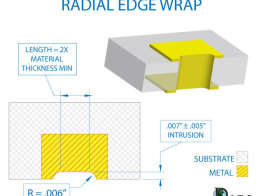

Wrapped Connections

Edge Wraps

Castellation

Solder Barriers &Control

(e.g. TiW, Polyimide, Nickel Oxide)

Supported Bridges

Spiral Inductor

Backside metallization

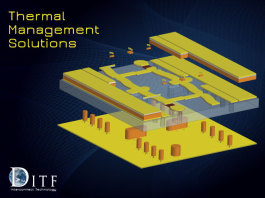

Thermal management solutions

● Solder, Epoxy, wire-bond attachments

● RoHS

● Example components -Coils, Sensors, Electrodes, Optical

>> RF / Microwave

>> Photonics

>> Medical